UNIQUE SOLUTIONS FOR MEAT & INDUSTRIAL PRODUCTIONS

Modernization of meat factory production:

Our company, having its development of machine vision (Triel Clear Vision), offers to carry out the production automation using intellectual systems for the product recognition and apportioning on the production line (automation of production using intelligent systems).

The system includes the implemented hardware and software complex of the controlled SCADA system Triel Pro Control (developed by 3L Company). The SCADA system includes a Triel Clear Vision module based on machine vision algorithms in the form of a neural network for the classification and recognition of all types of products.

The information received from the complex can be used by any enterprise systems (ERP, APS) on the platforms of such software products as: «1C», «Galaktika», «Parus», «SAP», «Microsoft Dinamis AX» (Navision Ahapta).

We provide high-quality technological solutions that allow our clients to gain additional advantages over competitors.

RS-100 Linerless Applicator with a tray sealer

RS-100 is a unique labeling complex designed to apply linerless labels to various products.

The complex has many advantages:

- can fit into any production line;

- the control, monitoring, information reading system can operate in a wide temperature range and be dust and moisture protected;

- the feeding conveyor ensures the centering of the packages on the conveyor;

- it is made of stainless steel and has adjustable legs;

- it has English menu;

- it is easy to clean and maintenance;

- spare parts and constant service support is available.

Compact applicators made by 3L Company are indispensable at any production with limited spaces. Our machines are widely used as a part of complete packaging lines. 3L applicators are highly productive, allowing our clients to run a complete production cycle.

LS-100 Linerless Applicator for salami

LS-100 labeling complex is designed for applying self-adhesive or linerless labels to various cylindrical products, such as bottles or sausages & salami etc.

The complex can fit into any production line. LS-100 can be made according to the individual requirements of the client, taking into account the peculiarities of the production in each individual case.

The compact, easy-to-set-up, and easy-to-use LS-100 applicator optimizes your production cycle.

Our applicators demonstrate smooth operation in high-workload environment.

We produce reliable and efficient labeling systems for a wide range of products. The units are produced in a compact design, which provides convenient placement. All models meet the key requirements for ergonomics and safety.

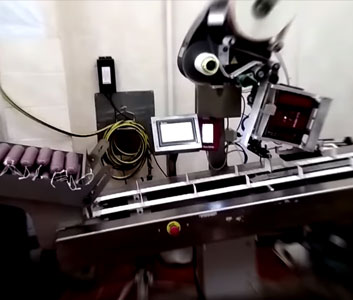

RS-100 Applicator for cylindrical shaped products

RS-100 labeling system is designed for applying linerless labels to various cylindrical products, such as bottles or sausages, etc.

The complex can fit into any production line.

RS-100 applicator has:

- a system for adjusting the width and tension of the packaging material with limiters with marked scale dimensions,

- pressure and guide rollers with the possibility of local lubrication and the possibility of disassembly without disassembling the entire body of the unit,

- stainless steel control cabinet with electrical components and PLC,

- a transparent protective screen to prevent personnel (materials) from getting into the cutting and sealing zones during the operation of the equipment and monitoring the operation of the equipment.

3L applicators are unique and created in accordance with the peculiarities of labeling of specific types of containers. The models are distinguished by an original design, which ensures efficient execution of work operations in automatic mode with maximum saving of working space, as well as in compliance with all requirements for ease of use and safety for personnel.

Machine for the formation stable products forms without casing

Forming machine is a specialized solution that allows quickly and efficiently produces uncoated sausages (kabanos, snacks, etc.).

Our forming machine is made of high quality stainless steel and is therefore durable and easy to work.

The advantage of the forming machine is easy to operate and cost-effective in maintenance.

3L equipment is distinguished by its multitasking, high durability, and practicality in operation.

Our solutions will allow you to get reliable and safe equipment that will ensure the production of quality products.

Dynamic scales

3L Dynamic scales (conveyor scales, checkweighing systems) is a reliable high-precision industrial solution. This control weighing equipment is designed to control 100% of the product weight, excluding the cases of dosing errors and guaranteeing a stable result.

3L checkweigher can be equipped with a metal detector for complex control.

Our dynamic scales have:

- stainless steel body frame,

- English control panel,

- integrated vibrations and temperature schemes,

- smooth adjustment of the conveyor speed,

- easy parameter settings.

The scales are easy to clean.

Equipped with high-quality components, the dynamic scales produced by 3L Company work correctly and without failures.

Product recognition, dynamic weighing and labeling system

Specialists of our company have their own machine vision developments. We have created a unique hardware and software complex controlled by the Triel Pro Control SCADA system.

The system includes:

- the implemented hardware and software complex controlled by the SCADA system Triel Pro Control (developed by TRIEL). The SCADA system includes a Triel Clear Vision module based on machine vision algorithms in the form of a neural network for the classification and recognition of all types of products,

- dynamic scales,

- labeling system using linerless labels.

Сustom-tailored service is the main principle of our work. Therefore, any client can rely on us at all stages of the project: consulting, planning or startup. We will certainly take into account all requirements and wishes of the client.

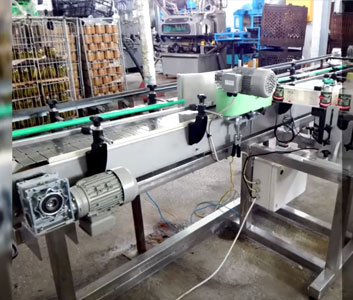

Marking machine for cans

3L marking machine for cans is designed for applying labels (self-adhesive or linerless) to cans.

Our catalog contains labeling systems designed for small, medium, and large industries.

By the production tasks, marking machine can include additional options according to the individual requirements of the Client.

All labeling equipment produced by 3L Company is regularly updated following modern standards and changing regulations. Marking machines are delivered to the site of the Client with a full package of documentation, which allows our customers to successfully carry out certification and validation of production processes. Highly professional technicians of our company provide a full range of services: preliminary consulting, joint development of technical specifications with the Customer, production, delivery, start-up, as well as personnel training, warranty, and post-warranty (service) maintenance.

RS-100 Linerless Applicator

RS-100 is a universal complex designed for labeling various products using linerless labels.

The applicator has many advantages:

- it can fit into any production line,

- it has the wear-resistant PVC belts on stainless steel guides with sliding pads made of wear-resistant material suitable for work at high temperatures,

- pressure and guide rollers have the possibility of local lubrication and the possibility of disassembly without disassembling the entire body of the unit,

- it is made of stainless steel control cabinet with electrical components and PLC,

- a transparent protective screen to prevent personnel (materials) from entering the cutting and sealing zones during the operation of the equipment and monitoring the operation of the equipment.

Our labeling complexes allow not only to ensure the automation of all labeling processes but also to minimize rejects due to the high accuracy and consistency of the equipment.

Conveyor systems of any complexity

Our production is equipped with modern metalworking machines, which allows us to succeed the most complex orders.

We offer various types of conveyors; our solutions can be easily adapted to the peculiarities and installation requirements of the Customer. 3L conveyor systems, together with sorting and picking devices, form an optimal production system.

Our team is experts in the field of equipment manufacturing. A careful approach to the production of conveyors allows achieving the highest quality in accordance with all the requirements of the Client.

3L is an engineering company specializing in the manufacturing of technologically sophisticated equipment:

- for marking trays/containers, cylindrical and square-shaped products with linerless labels;

- for the formation of stable products forms without casing (snacks, kabanos, uncoated sausages of different thicknesses, etc.);

- for cutting poultry wings with subsequent counting and packaging;

- dynamic conveyor scales;

- intellectual systems for the products recognition and apportioning on the production line (automation of production using intelligent systems);

- modernization of production facilities with the integration of machine vision in the form of a neural network for the recognition of any type of product (Triel Clear Vision module – self-engineered products by 3L Company).