Linerless

- Home

- Linerless

Linerless technology is one of the latest innovations. Linerless label refers to self-adhesive labels, but without a liner.

Benifits of Linerless technology

- Save label cost up to 40%;

- No waste after using labels;

- Reduced storage costs;

- Reduced pollution tax;

- Attractiveness of the packaging;

- Universal size of labels;

- The ability to print variable information on the inner side of the label: recipe, actions, percentage of calories, etc.

Our equipment for linerless:

Linerless applicator «RS»

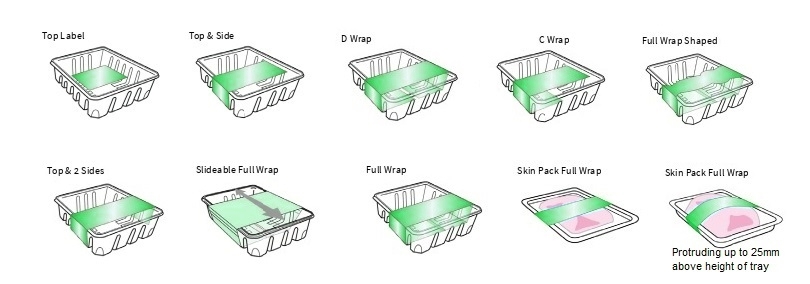

A universal complex for applying linerless labels providing high-quality product labeling in a variety of ways:

Main technical characteristics:

- MAX speed, packaging/min*

100

- Label sizes** L х W, mm

400 х 80

- Power supply network

V220

- Power

W650

*speed is customizable for the client and may be higher than stated in the standard configuration;

**the dimensions of the label are determined by the client for the packaging used.

What are the benefits of using our applicator?

- RS applicator can be used as a part of automatic filling lines in conjunction with various types of equipment.

- RS applicator can be connected to a line with control and dynamic scales (check-weigher) and print variable information about the weight of the product on the required label.

- RS applicator can be equipped with an inkjet, thermal transfer or thermal inkjet printer.

Intellectual systems for the products recognition and apportioning on the production line (automation of production using intelligent systems

The system includes:

- implemented hardware and software complex controlled by the SCADA system Triel Pro Control (developed by 3L Company). The SCADA system includes a Triel Clear Vision module based on machine vision algorithms in the form of a neural network for the classification and recognition of all type of product,

- dynamic scales,

- linerless labeling system.

3L TEAM is ready to develop and manufacture high-tech equipment according to your needs

Copyright © 2021. All rights reserved.